Nanoclay Modification and Compound Formulation for Foaming Linear Polypropylene

Case ID:

TEC2007-0160

Web Published:

7/21/2014

Description:

Introduction

Linear polypropylene is not ideal for making foams for sealing purposes due to poor melt strength. The attempts to overcome this limitation by cross-linking a portion of the linear polymer or by adding a long chained branched polymer have resulted in unwanted side effects, such as a reduction in recyclability. Additionally, long chain branched polymers are expensive and increase foam cost.

Description of Technology

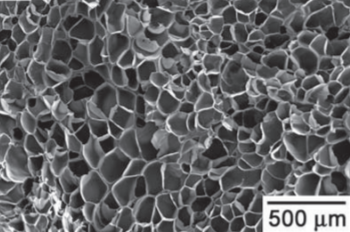

Michigan State University’s technology is a method for improving the foaming properties of linear polypropylene through the incorporation of organoclay (nanoclay) and a polymeric modifier. The resulting thermoplastic foam can be re-melted and reformed, unlike thermoset foams. Furthermore, the addition of organoclay increases stiffness and eliminates the need for cross-linking and adding a long chain branched polymer to achieve the appropriate melt strength for foaming.

Key Benefits

- Improved melt strength and foamability: No cross-linking or long chain branched polymer addition needed to allow proper foaming of the material.

- Environmentally friendly: Adding small amounts of nanoclay maintains the recyclability of the material.

- Less complex and improved processing: The invention uses a pre-blended formulation (master batch) to add to bulk linear polypropylene. Thus, there is no need for processors to deal with adding and dispersing the organoclay.

Applications

This invention is useful for improving the processing of linear polypropylene for making thermoplastic foams and for making the resulting foams recyclable. The foams produced using the method can be used for a variety of applications, such as primary and secondary seals in automobiles, weather seals, and instrument panels.

Patent Status

Patent issued, #9,279,046

Inventors

Krishnamurthy Jayaraman, Tanmay Pathak, Amit Chaudhary

Tech ID

TEC2007-0160

Patent Information:

| App Type |

Country |

Serial No. |

Patent No. |

File Date |

Issued Date |

Expire Date |

For Information, Contact:

Jon Debling

Technology Manager

Michigan State University - Test

deblingj@msu.edu